How RTP Integrity Tester Ensures Safety in Sterility Isolators

How RTP Integrity Tester Ensures Safety in Sterility Isolators

In drug and biotech fields, keeping a clean workspace is key to safe products and following rules. Transfer systems help move items safely in clean chambers without letting germs in. At MedIntegrity, we make top-notch testers to protect your work. This blog explains how these testers work, why they matter in clean chambers, and why you need them.

The Role of RTP Systems in Sterility Isolators

Transfer systems are built to move items, like samples or tools, into clean chambers safely. They keep the space germ-free. These systems are used in drug-making, biotech, and medical tool production, where dirt must be kept out.

Key Features of RTP Transfer Systems

Transfer systems are made carefully to keep things clean. Their main features are:

- Tight Seals: Parts lock together to block outside germs.

- Fast Moves: Lets items move quickly without losing cleanliness.

- Works with Many: Fits different chamber types and container sizes, making it flexible.

- Strong Materials: Made from tough metal or special plastics to handle cleaning processes.

These features make transfer systems vital for keeping a controlled space in clean chambers.

Importance of Maintaining Sterility in Isolators

Clean chambers create a super-clean space, needed for germ-free work. A break in cleanliness can cause:

- Product Contamination: Germs or dust can ruin product quality.

- Rule-Breaking: Not meeting FDA or other standards can lead to fines.

- Health Risks: Dirty products can harm users.

- Work Stops: Germ issues can pause production, costing money.

Testing transfer systems ensures they stay tight, protecting the chamber’s clean space.

The Functionality of RTP Integrity Testers

Testers for transfer systems are special tools. They check if the systems have leaks. By finding even tiny holes, these testers keep clean chambers safe during item moves.

How RTP Integrity Testers Operate

These testers often use a pressure drop method. It’s safe and doesn’t harm the system. The steps are:

- Hooking Up: The tester connects to the transfer system’s parts, making a sealed unit.

- Adding Air: The system is filled with air or safe gas to a set pressure, often up to 3000 Pa.

- Settling: The tester waits for the pressure to steady. This accounts for materials or room conditions.

- Watching: The tester checks for any pressure drop over time. A big drop means a leak.

- Saving Data: Results are stored, often sent wirelessly for quick review.

Our tester uses smart pressure tech for fast, exact results. It meets standards like GB/T 25915.7-2010 and ISO 14644-7:2004.

Factors Affecting the Performance of RTP Integrity Testers

Several things can change how well testers work:

- Material Types: The system’s materials, like metal or plastics, affect how pressure holds and settles.

- Room Conditions: Heat, dampness, and air quality can shift pressure readings. Tests need steady spaces.

- Tester Setup: Regular checks keep the tester’s sensors accurate.

- User Skills: Good training stops mistakes during setup and use.

By handling these factors, our testers give steady, trustworthy results.

Why are RTP Transfer Systems Essential for Sterility Isolators?

Transfer systems aren’t just helpful—they’re a must for keeping chambers clean, boosting safety, and making work smoother.

Enhancing Safety with RTP Integrity Testing

Testing transfer systems is key to protecting products and workers. By checking for leaks, these testers lower risks that could harm the chamber’s clean space.

Preventing Contamination Risks

A tiny leak in a transfer system can let germs in, causing:

- Germ Contamination: Bacteria or fungi can ruin products or cause illness.

- Dust Contamination: Dirt can mess up product purity.

- Chemical Contamination: Outside gases can change product makeup.

Regular testing stops these risks. It keeps transfers safe.

Ensuring Compliance with Industry Standards

Rule-makers, like the FDA, demand tight controls for clean work. Testers help meet standards like:

- 21 CFR Part 11: Keeps digital records safe and trackable.

- GMP Rules: Requires strong germ control steps.

- USP <1207>: Sets rules for system tightness.

Our testers give clear data and audit records, making rule-following easier.

Improved Efficiency in Sterility Maintenance

Testers for transfer systems make keeping things clean easier by:

- Cutting Downtime: Fast tests mean less work pauses.

- Automating Steps: Wireless links and software manage testing for many units.

- Tracking Results: Data storage makes audits simple.

These benefits let you focus on main tasks while keeping a clean space.

Long-Term Cost Savings through Reliable Testing

Using testers saves money over time:

- Avoiding Recalls: Catching leaks early stops costly product pulls.

- Longer Equipment Life: Testing spots wear, allowing fixes before big issues.

- Less Waste: Keeps products clean, cutting scrapped batches.

Our testers, like the one linked, are built for toughness and accuracy, giving lasting value.

MedIntegrity: A Trusted Supplier of RTP Integrity Testers

At MedIntegrity, we’re dedicated to improving drug testing with new tools. With over 15 years of know-how, we offer precise tools that meet top standards. Our testers are trusted by big names like BeiGene USA, Inc., and Sunny Pharmaceutical.

Overview of MedIntegrity’s Expertise and Product Offerings

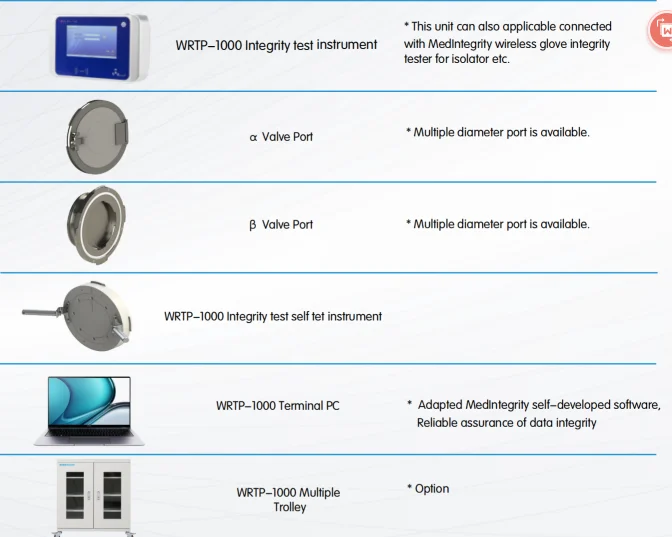

We focus on many testing tools, including:

- Transfer System Testers: Our model has wireless links, IP65 protection, and exact sensors.

- Glove Testers: Check gloves in chambers for holes.

- Filter Testers: Ensure filter systems work right.

- Water Analyzers: Measure carbon in drug water systems.

Our products follow FDA, GMP, USP, and EP rules, ensuring dependability. The tester stands out, offering wireless data and strong software for easy use.

Why Choose MedIntegrity for Your Sterility Needs

We’re proud of our quality and service:

- Proven Skills: Years of work in drug testing.

- Worldwide Reach: Helping thousands of drug firms globally.

- Full Support: From setup to upkeep, we offer guides and procedures.

- Customer Focus: Solutions tailored to your needs.

Contact us to see how we can help with your clean testing needs.

Conclusion

Summary of the Importance of RTP Integrity Testing for Safety and Compliance

Testing transfer systems is vital for safe, rule-following clean work. By ensuring transfer parts are leak-free, these testers protect chambers from germs, keep products safe, and meet tough rules. Working with a trusted supplier like MedIntegrity gives you the tools and support for a secure, smooth operation. Visit our homepage to check out all our testing tools.

FAQs About RTP Integrity Testers

What is an RTP integrity tester used for?

A tester for transfer systems checks if Rapid Transfer Port systems in clean chambers have leaks. It spots holes that could let germs into the chamber. This keeps drug and biotech work clean. The tester uses methods like pressure drop for accurate, trackable results. It supports following strict rules.

How often should an RTP integrity test be conducted?

How often you test depends on use, rules, and risk checks. Usually, tests happen before and after work cycles to keep things clean. Busy facilities may test daily or per shift. Maintenance plans often schedule tests monthly or every few months. Check your guides and rule books for exact advice.

Can an RTP integrity tester be used with all types of isolators?

Yes, testers, like our model, work with most clean chambers that have transfer systems. They fit various part setups and can adjust for different materials and sizes. But testers need setup for specific chamber designs and room conditions to give accurate results.