Understanding Filter Integrity Tester Functions in Modern Testing Methods

Understanding Filter Integrity Tester Functions in Modern Testing Methods

Filter integrity testing holds a key position in pharmaceutical and biotechnological quality control. It makes sure that sterilizing-grade filters work properly. For example, tests such as bubble point and diffusion flow are required for batch release and process validation. Employ standard filters with established integrity traits to evaluate the filter integrity tester’s performance. Such standardization aids regulatory adherence. It also guarantees that sterility stays intact during manufacturing.

What Regulatory Standards Govern Filter Integrity Testing?

Various global guidelines set rules for testing and recording filter integrity. These cover USP <1207>, which deals with sterile product package integrity. They include PDA Technical Reports. And they encompass ISO 13408-2, which details aseptic processing standards. To comply, you need thorough documentation. Validated test methods are essential, too. Plus, traceable records play a vital role.

Verify that the user manual, technical specifications, installation drawings, and calibration certificates for the filter integrity tester are all in place. This paperwork is crucial for audits and validation procedures. Without it, compliance becomes challenging.

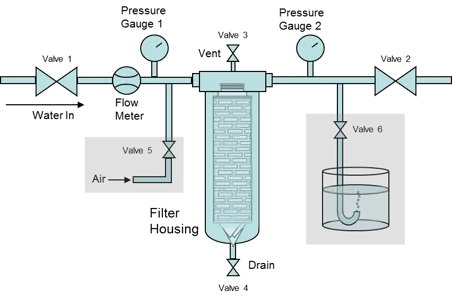

How Does a Filter Integrity Tester Function in Practice?

Filter integrity tests remain non-destructive. This means you can check filters after use without risking sterility. Such methods spot issues like membrane breaks, wetting faults, or weak seals. Keeping the aseptic barrier strong is vital. Otherwise, you might face product recalls or health dangers. Therefore, these tests provide peace of mind in production settings.

Examine the basic operations of the filter integrity tester. Focus on its skill in applying various test pressures with precision. This matters a lot for tests like bubble point and pressure hold. In those cases, exact control decides if results are trustworthy. So, reliable performance here supports overall quality.

What Capabilities Distinguish Modern Filter Integrity Testers?

Today’s testers show great sensitivity. They can find tiny defects at the micron level. This works for many filter types, including disc, pleated, and capsule varieties. A digital sensor boosts the accuracy and reliability of test outcomes. This holds true especially for setups with touchscreen displays and user control systems. As a result, operators get consistent results every time, which builds confidence in the process.

Which Filter Integrity Testing Methods Are Commonly Used?

In bubble point testing, you apply pressure to a soaked filter membrane. Air pushes out the liquid at a certain point. The pressure which the first bubbles show up indicates the pore size. This approach suits hydrophilic membranes well. It has become a go-to method in many labs because of its straightforward nature and effectiveness.

When Should Diffusion Flow Testing Be Applied?

Diffusion flow checks the gas passage through a wet membrane. It does this at pressures below the bubble point. This test fits hydrophilic filters in sterile filtration tasks. There, you need exact gas permeability readings. Consequently, it provides detailed insights into filter performance under real conditions.

What’s Unique About Water Intrusion Testing for Hydrophobic Filters?

Water intrusion testing (WIT) suits hydrophobic membranes in gas filtration. It gauges water entry under set conditions to verify the barrier’s strength.

When Is Pressure Hold or Pressure Decay Suitable?

For setups where measuring flow directly proves tough, pressure hold or decay methods come in handy. They track pressure shifts over time to pinpoint leaks or setup problems. These options prove useful in complex systems, ensuring nothing slips through the cracks during checks.

How Are Filter Integrity Testers Integrated into Production Environments?

In-line testing lets you assess filter integrity right in the process line. On the other hand, off-line testing gives more options. People often use it for validation or after-batch reviews.

What Automation Features Enhance Workflow Efficiency?

Current systems link easily with SCADA or MES platforms. This allows real-time data collection and oversight. These electronic tools also follow 21 CFR Part 11 rules. The instrument includes an audit trail function. It fully satisfies data integrity demands. This built-in capability helps teams maintain records without extra hassle.

What Criteria Should Guide Filter Integrity Tester Selection?

Sensitivity and Accuracy

Spotting small defects with precision ensures dependable results. For instance, the bubble point pressure reading ought to fall within ±10% of the standard filter’s certified value. Such exactness prevents false readings and supports trust in the equipment.

Test Efficiency

How fast a test runs affects the overall output in manufacturing. Quicker times boost productivity. Yet, they must not sacrifice precision.

Compatibility

A good tester handles a broad array of filters accurately. It delivers solid integrity data for membrane, depth, cartridge, and capsule types. This versatility means one device can serve multiple needs, saving time and resources in diverse production lines.

Compliance

Features like calibration certificates, digital records, and secure access with passwords align with GMP standards. During inspections, these elements show that the system meets expectations. They provide the proof auditors seek, making the whole setup more robust.

What Challenges Commonly Affect Filter Integrity Testing?

Factors such as room temperature, moisture levels, and air pressure can alter test results. To counter this, regular calibration becomes necessary. It adjusts for these changes, so outcomes stay true and useful. Ignoring them might lead to unreliable data, which no one wants in quality control.

Can Operator Errors or Setup Issues Impact Results?

Wrong wetting methods or crooked tubing often cause misleading results, either too high or too low. Also, align the test head properly with the filters.

What Innovations Are Shaping the Future of Filter Integrity Testing?

Elements like touchscreens, self-checking diagnostics, and remote controls have improved how users interact with these devices. Cloud storage adds another layer by keeping records accessible across multiple sites. Together, these upgrades make testing easier and more connected, fitting well into modern facilities.

A high-definition, large-size color touch screen displays plenty of test details. It can pick and adjust programs that fit the filter at hand automatically.

What Role Does Predictive Maintenance Play?

Algorithms powered by AI look at how the device is used. They spot signs of trouble early, before breakdowns happen. This approach to predictive maintenance cuts unplanned stops. It also lengthens the tool’s useful life. Overall, it brings cost savings and steadier operations to the table.

Who Is Leading in Advanced Filter Integrity Tester Solutions?

For over ten years, Integridad médica has earned a strong name in pharmaceutical analytical tools. Their deep knowledge of filter integrity testing stands out. They provide a full range of products that blend rule-following with simple operation. Take their top model, the Comprobador de integridad de filtros V8.0. It offers fast work speeds alongside reporting that fits GMP rules. For labs with limited space or focused on validation, the smaller Modelo V6.5 covers all main test types. It includes sharp analysis features, too.

MedIntegrity does more than just sell hardware. They give complete help, from setup to qualification services like IQ/OQ/PQ. This ensures smooth rollout in controlled settings. Their testing approaches meet FDA and GMP rules. They also align with USP and EP standards. Such thorough support makes them a reliable partner for quality teams everywhere.

Beyond testers, their lineup features tools like freezing point osmometers for checking osmolality. You will find capsule filters and PES membranes for sterile tasks as well. All these items work together to build strong quality control flows. This integrated approach helps companies stay ahead in regulated industries, where every detail counts toward safety and efficiency.

FAQ

Q1: How often should filter integrity testers be calibrated?

A1: Follow the maker’s advice or your own SOPs for calibration timing. Doing so keeps test precision up to regulatory levels. Regular checks prevent drift and maintain high standards over time.

Q2: Can one tester handle both hydrophilic and hydrophobic membrane tests?

A2: Yes, advanced models manage bubble point, diffusion flow, and water intrusion tests. They work across various membrane kinds. This flexibility saves on equipment needs and streamlines lab processes effectively.

Q3: What is the difference between bubble point testing and diffusion testing?

A3: Bubble point finds the pressure to push air through a wet membrane. Diffusion testing looks at steady gas flow under that pressure. Both verify filter strength but use distinct ideas suited to different uses. Understanding this helps pick the right method for your specific filtration goals.