How Different Diameter RTP Ports Impact Integrity Testing and Which Instruments to Use

How Different Diameter RTP Ports Impact Integrity Testing and Which Instruments to Use

In aseptic manufacturing environments, Rapid Transfer Ports (RTPs) are critical components used to ensure the sterile transfer of materials between isolators, cleanrooms, and containment systems. The integrity of these ports directly affects contamination control and product safety. As part of the validation process, integrity testing—using methods like pressure decay, pressure hold, and flow testing—is essential. However, RTP port diameter plays a pivotal role in test performance and accuracy. This article explores how different RTP port sizes impact integrity testing and which instruments best suit various configurations.

Impact of RTP Port Diameter on Integrity Testing

The physical characteristics of RTP ports, particularly their diameter, greatly influence the sealing efficiency and leak detection sensitivity during integrity testing procedures.

Variability in RTP Port Sizes and Its Relevance

RTP ports come in several standard dimensions, including 105mm, 190mm, and custom oval or non-circular ports. These different geometries influence the total surface area that must be sealed and tested. Larger RTP ports inherently present more sealing surface area, which increases the number of potential leak paths. Conversely, smaller ports have reduced surface interfaces, allowing for faster stabilization and simpler detection schemes.

Moreover, port geometry affects compatibility with test devices. Oval RTP ports may require specially designed fixtures or adaptable sealing mechanisms to achieve proper alignment and test consistency. Testing systems need to be flexible enough to handle these different shapes without any compromise to data integrity or regulatory compliance.

How Port Diameter Affects Test Sensitivity and Accuracy

The sensitivity of leak detection systems must scale with the RTP port size. Larger ports contain more internal volume, so tests for pressure decay must have finer resolution to detect minute leaks. Also, larger diameters tend to lead to longer stabilization times due to increased air volume displacement during testing.

Smaller RTP ports allow for faster stabilization and faster pressure equilibration, which are beneficial in high-throughput environments. The volume-to-surface area ratio also plays a role: as port diameter increases, the internal volume with respect to surface area increases, which may dilute the effects of small leaks on the pressure reading by demanding more advanced sensors to reliably detect them.

Key Integrity Testing Methods for RTP Ports

The selection of the right RTP testing method is highly essential for ensuring accuracy and reproducibility. Each technique has unique strengths depending on port dimensions and operational needs.

Pressure Decay Testing for Leak Detection

Pressure decay testing involves pressurizing the sealed RTP system and monitoring the drop in pressure over time. It is widely used because of its simplicity and effectiveness in identifying leaks.

Port size directly influences the pressure drop rate. Larger RTP ports require more sensitive instrumentation to detect minimal pressure changes over broad surfaces. Establishing appropriate baseline values is essential for each port diameter to ensure consistent results. Best practices include calibrating the system specifically for each port type to accommodate variations in geometry and internal volume.

Pressure Hold Testing for Stability Assessment

Pressure hold testing maintains a constant pressure within the sealed RTP interface while monitoring its stability over a specified duration. This method is particularly useful in environments requiring extended observation for validation.

Larger RTPs may need longer hold times due to their greater air volume and the thermal equilibration required across wider areas. Often, small-diameter ports can be evaluated with shorter durations without sacrificing accuracy. The environmental conditions must also be tightly controlled regarding temperature and humidity to avoid fluctuations that may affect test readings.

Flow Testing for Continuous Leak Monitoring

Flow testing continuously monitors airflow through the RTP interface to detect real-time leakage. It is especially beneficial for large or irregularly shaped ports where pressure-based methods may struggle to provide consistent sensitivity.

This method excels in applications involving 190mm or oval-shaped ports where surface irregularities may impair seal integrity. When applying flow sensors, calibration must account for port dimensions and expected flow rates to ensure valid results across all geometries.

Instrument Selection Based on Port Characteristics

The effectiveness of RTP integrity testing relies heavily on selecting instruments that align with port specifications.

Matching Instrument Capabilities with Port Size Requirements

Larger ports require instruments capable of handling broader flow ranges and higher pressure resolution. Smaller ports benefit from equipment that delivers rapid stabilization and fine detection thresholds. Instruments should be adaptable to both round and oval shapes without needing extensive hardware modifications. Modular systems that support multiple testing techniques within one platform provide greater flexibility across varied applications.

Features to Look For in a Reliable RTP Testing System

Compatibility Across Multiple Port Types:

An effective testing instrument must support Alpha and Beta components regardless of their shape or size. This ensures seamless integration across all types of RTP interfaces without requiring separate tools for each configuration.

Multi-mode Testing Support (Pressure Decay, Hold, Flow):

Systems that enable switching between pressure decay, hold, and flow tests within a single unit enhance operational efficiency. This flexibility allows users to choose the most appropriate method based on port dimensions or product sensitivity.

Regulatory Compliance and Data Integrity Features:

The testing methods comply with the requirements of FDA and GMP regulations, as well as USP and EP. Instruments must also comply with FDA 21 CFR Part 11 for electronic records, EU Annex 1 for sterile manufacturing, and GAMP 5 standards for computerized system validation.

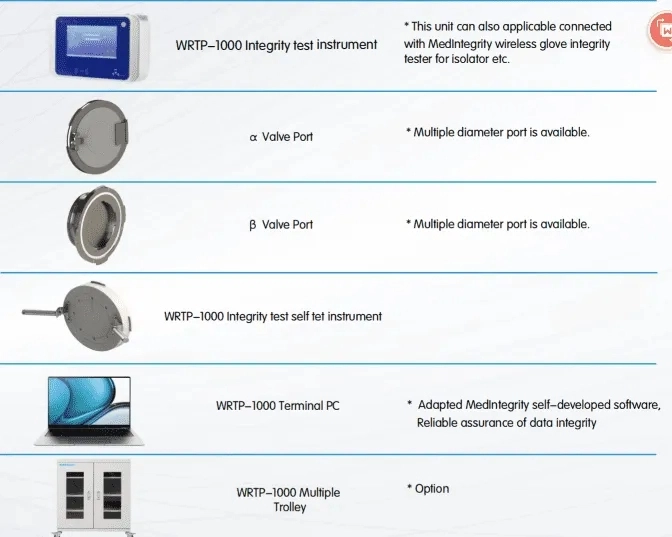

Advantages of Using MedIntegrity RTP Testing Systems

MedIntegrity offers advanced solutions tailored for pharmaceutical-grade environments where precision and compliance are non-negotiable.

Versatility Across Different RTP Port Diameters and Shapes:

As a value-added partner, we provide customers with a variety of solutions for testing processes, problem analysis, and laboratory research. 메드인티그리티 systems support a wide range of port sizes including small 105mm ports to large 190mm or oval formats with interchangeable adapters.

Integrated Multi-method Testing in One System:

Users can perform pressure decay, hold, and flow tests without switching devices—ideal for facilities managing various RTP formats or transitioning between applications.

Compliance with Industry Standards Ensures Quality Assurance:

MedIntegrity’s systems WRTP-1000 meet stringent global pharmaceutical standards, helping ensure batch sterility during aseptic transfers.

User-Friendly Interface Improves Operational Efficiency:

Simplified interfaces reduce operator training time while minimizing setup errors, ensuring repeatable outcomes even in high-throughput environments.

Applications Across Life Sciences Industries

RTP integrity testing plays a pivotal role in maintaining sterility across various critical operations in life sciences.

Pharmaceutical Manufacturing Environments:

RTP ports are commonly used in cleanroom material transfers. Integrity testing prevents contamination during transitions between sterile zones such as isolators and fill-finish lines.

Biologics Production Facilities:

In biologics manufacturing where sensitive proteins or cells are involved, maintaining sterile boundaries during raw material transfers is crucial—especially across different classified clean zones.

Medical Device Packaging Cleanrooms:

Sterile packaging environments rely on validated RTP systems to maintain product integrity during final assembly or packaging under ISO Class 5 conditions or better.

MedIntegrity: Your Partner in Laboratory Equipment Solutions

MedIntegrity provides advanced testing systems designed for high-stakes environments such as pharmaceutical cleanrooms. Their RTP integrity testing solutions are engineered to support multiple port sizes, deliver reliable results across various test methods, and ensure compliance with global regulations. With a strong focus on user experience, integration capability, and after-sales service, MedIntegrity stands as a trusted partner in aseptic process validation.

Summary of Key Insights

RTP port diameter plays a critical role in the outcome of integrity testing procedures. Whether using pressure decay, hold, or flow methods, the physical dimensions of the port influence calibration settings, detection sensitivity, and overall test accuracy. Selecting the right instruments—such as those provided by MedIntegrity—ensures compatibility with various port types while maintaining regulatory compliance. A strategic approach to instrument selection based on port characteristics enhances contamination control and process reliability.

FAQs:

Q1: Can one instrument handle different sizes of RTP ports?

A: Yes. Modern systems like those from MedIntegrity are designed to support multiple diameters including both round and oval ports through adaptable interfaces.

Q2: Which test method is recommended for larger diameter RTP ports?

A: Flow testing is often preferred for larger ports due to its ability to continuously monitor leakage over broader surface areas where pressure-based methods may be less sensitive.

Q3: How often should RTP integrity tests be performed?

A: Testing frequency depends on the criticality of the application but is typically done before each material transfer or at regular intervals defined by GMP protocols.