How to Avoid Bag Integrity Failures: Common Issues and Mitigation Techniques

How to Avoid Bag Integrity Failures: Common Issues and Mitigation Techniques

In industries where product safety, sterility, and following the rules are very important, the quality of packaging—especially bags—is a big deal. Bag integrity is a bag’s power to keep its protective layer strong against germs and damage through its whole life. Using a good bag integrity tester is key. It makes sure packaging meets high standards, which helps avoid expensive problems.

The Importance of Bag Integrity in Packaging

Keeping bags intact is more than just a good idea. Often, it’s required by law for safety.

Role of Bag Integrity in Product Safety and Compliance

Bag integrity makes sure what’s inside stays clean, sterile, and safe. This is especially important in the pharmaceutical, food, and medical device industries. In these fields, a single leak can cause major health problems or get a company in trouble with regulators. The testing methods satisfy the requirements of the FDA and GMP regulations, as well as the requirements of USP and EP. This just goes to show how important it is for packaging systems to be checked with the right testing tools.

Industries Where Bag Integrity is Critical

Bag integrity is a huge deal in fields like pharmaceuticals, biotechnology, food processing, chemical manufacturing, and healthcare. These industries need to be completely clean. So, even a tiny leak can ruin a product or make it unsafe.

Consequences of Bag Failure in Sensitive Applications

When a bag fails, it can lead to contamination, spoiled products, and product recalls. Besides that, it can cause financial loss and damage to a company’s name. In regulated fields like pharmaceuticals or biologics manufacturing, these failures might also mean not meeting FDA or GMP standards.

Common Causes of Bag Integrity Failures

Understanding why bags fail helps companies stop these problems before they start.

Material Defects and Inconsistencies

When the bag’s material isn’t the same thickness all over, or if the materials are low-quality, weak spots can form. These spots are where leaks can easily happen. These problems often come from mistakes in making the bags or from using poor-quality raw materials.

Sealing Process Issues

Great materials don’t matter if the seal is bad. Not enough heat or pressure when sealing can create weak bonds. What’s more, things like dust or bits of product on the seal line can stop the seal from closing right. This can cause tiny, hard-to-see leaks.

Mechanical Stresses During Handling and Transportation

Bags can get tossed around during shipping or in the warehouse. This can cause scrapes, holes, or crushing that makes the bag weaker. Storing bags the wrong way, like in places with very high or low temperatures or humidity, can also break down the packaging material over time.

Environmental Factors

Things in the environment like humidity, temperature, and UV light can make the material break down faster, especially plastics. This hurts its ability to bend and protect what’s inside. Furthermore, chemical reactions between the product and the bag can happen. This can make the bag brittle or leaky.

Methods for Detecting Bag Integrity Issues

Finding potential problems early is very important for quality control. Looking at the bag is a start, but you can’t see tiny leaks that way. For better, more trustworthy results, standard physical tests like vacuum decay, pressure decay, and bubble emission testing are needed.

For today’s fast-paced work environments, new testing tools give better and faster answers. A special bag integrity tester does pressure-based tests automatically and is very accurate. It provides real-time validation for all sorts of bag types and sizes. Plus, these tests don’t damage the bag, so it can still be used.

Mitigation Techniques to Prevent Bag Integrity Failures

Stopping leaks starts with smart design choices and strict controls during production. This process includes a few key things. First of all, it means choosing top-notch, certified films and laminates. It also involves making the sealing process better by calibrating equipment regularly and using in-line inspection systems. Finally, making sure bags are handled and stored correctly through staff training and protective packaging is crucial.

Role of Bag Integrity Testers in Quality Assurance

Automated testers make finding leaks much simpler. They also make it easier to track results for each production batch. This is really important for being efficient and following the rules.

How Bag Integrity Testers Work

These testers work by pumping air into the bag up to a certain pressure under controlled conditions. Then, they watch to see if the pressure holds over a set time. The process is mostly automatic. Once the operator starts the test, the system fills the bag with air and stops when it hits the target pressure. They have some great features. For example, you can program the inflation pressures and see real-time pressure graphs. They also have automatic defect classification, alarms that buzz for failures, and thorough data logging abilities—all things a modern QA lab needs. Tests include pressure retention timing and automated pass/fail results based on this behavior. And when set up right, all of this is done without hurting the test items.

MedIntegrity: Trusted Supplier of Laboratory Testing Equipment

MedIntegrity is a top company for exact testing solutions made for high-stakes industries like pharmaceuticals and biotech manufacturing. As a helpful partner, MedIntegrity gives customers many solutions for their testing processes, problem analysis, and laboratory research.

Expertise in Quality Control and Regulatory Compliance

The company’s testing methods are compliant with FDA and GMP regulations. This makes MedIntegrity’s tools perfect for regulated environments. These places need data that can be tracked and that matches world standards like ASTM F2095. Our team is also active in drafting and creating industry standards and regulations in China.

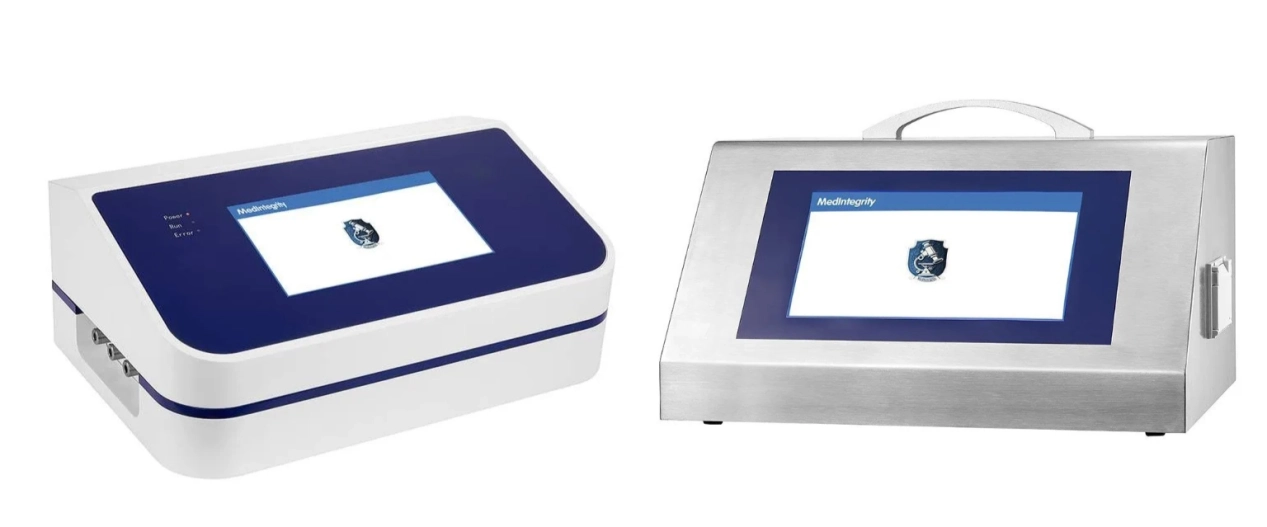

Featured Products for Bag Integrity Testing

MedIntegrity offers specialized models made for finding all kinds of leaks, including the BGT-120 (PD-PS02-3) en BGT-200 (PD-PS02-2) models. These models are made just for testing the integrity of many different bags. Their advanced features mean you can use them for other things, too, like glove leak detection on isolators and filling lines. They support custom pressure settings, programmable retention times, and real-time pressure display interfaces. Thus, they can accurately tell the difference between good and defective items based on pressure behavior logic algorithms.

Support Services and Custom Solutions

MedIntegrity also offers tech support that covers calibration procedures, guides for replacing components, and training for operators. Plus, all of this is supported by a global distribution network in more than 40 countries worldwide.

FAQs

Q1: What is a bag integrity tester and why is it important?

A: A bag integrity tester is a tool used to check if a sealed bag is airtight under certain pressure conditions. It’s important because it helps keep products safe by finding leaks that could let germs in or break the protective barrier—which is especially vital in pharmaceutical packaging where contamination risks must be kept as low as possible.

Q2: How often should bag integrity testing be performed?

A: The frequency depends on how risky the situation is. For critical items like sterile product bags, testing should be done regularly, following the facility’s Standard Operating Procedures (SOPs), which are in line with GMP protocols. For instance, checks might be needed for every new batch of bags, or from time to time during storage, to make sure their integrity holds up.

Q3: Can bag integrity testing be done without damaging the package?

A: Yes. Non-destructive methods like pressure retention analysis let packages be tested without making them unusable. Modern testers, such as those from MedIntegrity, can find leaks reliably without hurting the tested items when they are set up correctly.