How the Bubble Leak Test Ensures Filter Integrity in Critical Applications

How the Bubble Leak Test Ensures Filter Integrity in Critical Applications

In fields where safety, cleanliness, and dependability are essential, ensuring the strength of filtration systems is vital. The bubble leak test, a key method for checking filter quality, plays a big role in making sure filters work well in tough situations. At ความเป็นปอด, we focus on offering top-notch tools for testing filter strength. These tools help industries meet strict rules while keeping their work excellent. This blog looks at the bubble leak test, its ideas, uses, and why it’s so important for industries like medicine, food, and medical equipment making.

Overview of the Bubble Leak Test Method

The bubble leak test is a common way to check the quality of filters in important tasks. Its ease, precision, and gentle approach make it a top pick for industries that need filtration systems to keep products safe and good.

Definition and Purpose of the Bubble Leak Test

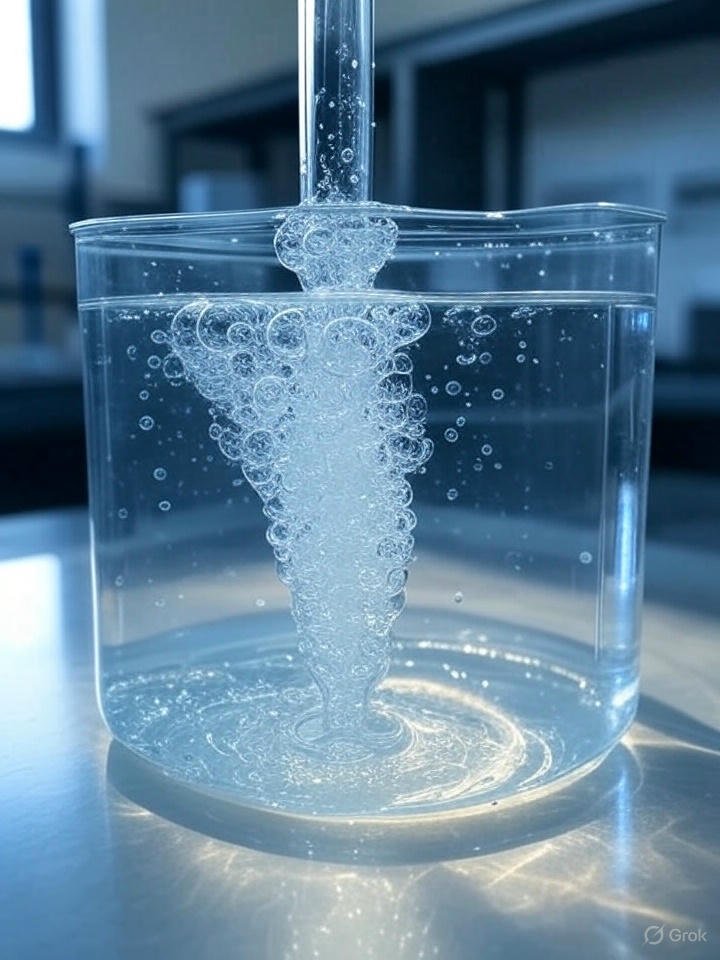

The bubble leak test uses pressure to find flaws or holes in filter materials. It does this by watching for gas bubbles in controlled settings. A filter is soaked with a liquid, usually water or a special test mix. Then, gas pressure is added. If the filter is strong, no bubbles show up below a certain pressure level. But if there are flaws, gas leaks through, creating visible bubbles. The main goal is to confirm that a filter’s holes are the right size. This ensures it can remove dirt without slowing down the flow.

Importance of the Bubble Leak Test in Critical Applications

In fields where dirt can cause big problems—like unsafe medicines or germs in food—the bubble leak test is crucial. It offers a steady, repeatable way to check filter performance. This helps meet rules set by groups like the FDA, GMP, USP, and EP. By finding even tiny flaws, the test protects product quality. It also keeps users safe, whether they are patients, customers, or machines.

The bubble leak test gives quick, clear proof of filter strength. This makes it a key tool for quality checks. Now, let’s explore the science that makes this method work so well.

Key Principles Behind the Bubble Leak Test

Knowing the science of the bubble leak test helps us value its accuracy and dependability. The method relies on basic physical rules about how gases work with wet filters.

The Science of Surface Tension and Capillary Action

The bubble leak test depends on surface tension and capillary action in a filter’s holes. When a filter is wet, liquid fills its holes. This creates a barrier held by surface tension. The tension stops gas from passing through until a certain pressure, called the bubble point, is reached. At this pressure, gas pushes past the liquid’s tension, forming bubbles. By controlling and measuring this pressure, testers can check if the filter’s hole size matches its requirements.

Pressure Thresholds and Their Role in Detecting Leaks

The bubble point is the lowest pressure needed to push gas through the biggest holes of a wet filter. If bubbles appear before this point, it shows flaws like oversized holes or tears. Testers compare the bubble point to the filter’s standards. This helps spot damaged filters. The method ensures even tiny flaws are found. This keeps the filter reliable for important tasks.

With these ideas clear, let’s look at how the bubble leak test is used in different fields.

Applications of the Bubble Leak Test Across Industries

The bubble leak test’s flexibility makes it vital in many areas. Its ability to ensure filter strength supports key processes where dirt risks are not allowed.

Use in Pharmaceutical Manufacturing

In medicine making, filters clean liquids, gases, and air. The bubble leak test checks that these filters can remove germs and bits. This ensures drug safety and follows rules. For instance, our V8.0 Filter Integrity Tester meets the latest data strength needs. It’s perfect for medicine tasks where tracking and following rules are key.

Application in Food and Beverage Production

The food and drink industry uses filtration to keep products clean and safe. The bubble leak test confirms that filters for tasks like water cleaning or drink clearing have no flaws. This stops germs or bits from spoiling products. It ensures products meet high safety rules and customer hopes.

Role in Medical Device Sterilization

Medical tools, like those for surgery or tests, need clean settings. The bubble leak test ensures filters used in cleaning processes are strong. This prevents dirt that could harm patients. Our V6.5 Filter Integrity Tester offers precision and ease. It helps medical tool makers keep high standards.

Now that we’ve seen its uses, let’s go over the steps to do a bubble leak test.

Steps Involved in Conducting a Bubble Leak Test

Doing a bubble leak test needs careful setup and action to get true results. Here’s a clear guide to the process.

Preparation and Setup of the Testing Equipment

Good setup is key for trustworthy results. Follow these steps:

- Pick the right filter: Make sure the filter works with the test liquid and task.

- Soak the filter: Use water or a special wetting mix to fill the filter’s holes fully.

- Attach the filter to the tester: Connect the filter securely to a filter integrity tester. Our V8.0 model ensures no leaks in the setup.

Selection of Appropriate Testing Parameters

Choose settings like test pressure and wetting mix based on the filter’s details and industry rules. For example, medicine tasks may need specific pressures to follow USP or EP rules.

Execution of the Testing Procedure

After setup, start the test:

- Add pressure slowly: Raise the gas pressure on the filter’s upstream side.

- Watch for bubbles: Look at the downstream side for bubbles. Use a submerged tube or visual check.

- Note the bubble point: Record the pressure when steady bubbles appear. Compare it to the filter’s standard bubble point.

Monitoring for Bubble Formation and Pressure Drops

During the test, check for early bubbles or sudden pressure drops. These show flaws. Tools like our V8.0 log data in real time. This improves accuracy and tracking.

Next, let’s look at the benefits of the bubble leak test.

Advantages of Using the Bubble Leak Test for Filter Integrity

The bubble leak test has many perks. These make it a top choice for checking filter strength.

Non-Destructive Nature of the Testing Method

Unlike some harsh tests, the bubble leak test lets filters be reused if they pass. This saves money and reduces waste. It’s especially helpful in fields where filters are costly or used in valuable tasks.

High Accuracy and Reliability in Detecting Faults

The test spots even small flaws. This ensures only strong filters are used in key tasks. Its sensitivity to pressure changes and bubbles gives exact results. This lowers the chance of missing flaws.

Even with its strengths, the bubble leak test has some hurdles to overcome.

Challenges and Limitations of the Bubble Leak Test Method

The bubble leak test is very useful but has some limits. Knowing these helps users improve their testing.

Factors That May Affect Accuracy

Several things can change test results. These need careful control:

Environmental Conditions During Testing

Temperature, humidity, and air pressure can affect bubbles and pressure readings. Testing in a stable setting reduces these issues.

Variability in Filter Materials

Different filter types, like water-repelling or water-attracting materials, may need specific wetting mixes or pressure settings. Users must adjust the test to the filter’s traits.

Addressing Common Misconceptions About the Test

Some think the bubble leak test is too hard or unreliable. In truth, with good training and tools, it’s simple and very accurate. Automated testers, like ours at MedIntegrity, make the process easier and more dependable.

At MedIntegrity, we work to solve these challenges with smart tools.

MedIntegrity: A Reliable Supplier for Filter Integrity Testers

We are proud to be a trusted partner for industries needing precise testing tools. At MedIntegrity, we offer new solutions to ensure filter strength and rule-following.

Commitment to Quality and Precision in Filter Integrity Solutions

Our goal is to provide dependable, easy-to-use testers that meet critical industry needs. We serve thousands of customers worldwide, including top medicine companies like BeiGene. We focus on quality and new ideas.

Range of Products Tailored to Meet Industry Needs

Our products include advanced filter integrity testers like the V8.0 and V6.5. These are built for precision and meet FDA and GMP rules. They include tracking functions and electronic signatures to follow 21 CFR Part 11 rules. This ensures data strength.

| Product | Key Features | Ideal Uses |

| V8.0 | Tracking, wireless connection, high-precision sensors | Medicine making, medical tool cleaning |

| V6.5 | Small size, quick testing, easy interface | Food and drink, general industry tasks |

For more details or to talk about your needs, contact us today.

Conclusion

The bubble leak test is a crucial tool for ensuring filter strength in fields where safety and rules matter. Its gentle approach, high precision, and use in medicine, food, and medical tool making make it essential. At MedIntegrity, we support your quality efforts with top-tier filter integrity testers. By choosing our tools, you ensure your filtration systems meet high standards. This protects your products and your reputation.

FAQs About the Bubble Leak Test Method

Q1 What Types of Filters Can Be Tested with the Bubble Leak Method?

A1 The bubble leak test works for many filters, like membrane, cartridge, and capsule filters. These are common in medicine, food, and medical tool tasks. Both water-repelling and water-attracting filters can be tested. Just use the right wetting mix for the filter’s traits.

Q2 Is Special Training Required to Conduct a Bubble Leak Test?

A2 The bubble leak test is simple but needs training for accurate results. Operators should know filter details, test settings, and tool use. Our testers, like the V8.0 and V6.5, have easy interfaces. This reduces training needs. Still, we suggest training to ensure rule-following and precision.

Q3 How Often Should Filters Be Tested for Integrity?

A3 Testing frequency depends on industry rules and task needs. In medicine, filters are often tested before and after use. This ensures cleanliness and rule-following. Regular testing, like daily or per batch, is advised for key tasks. This keeps performance steady and safe.